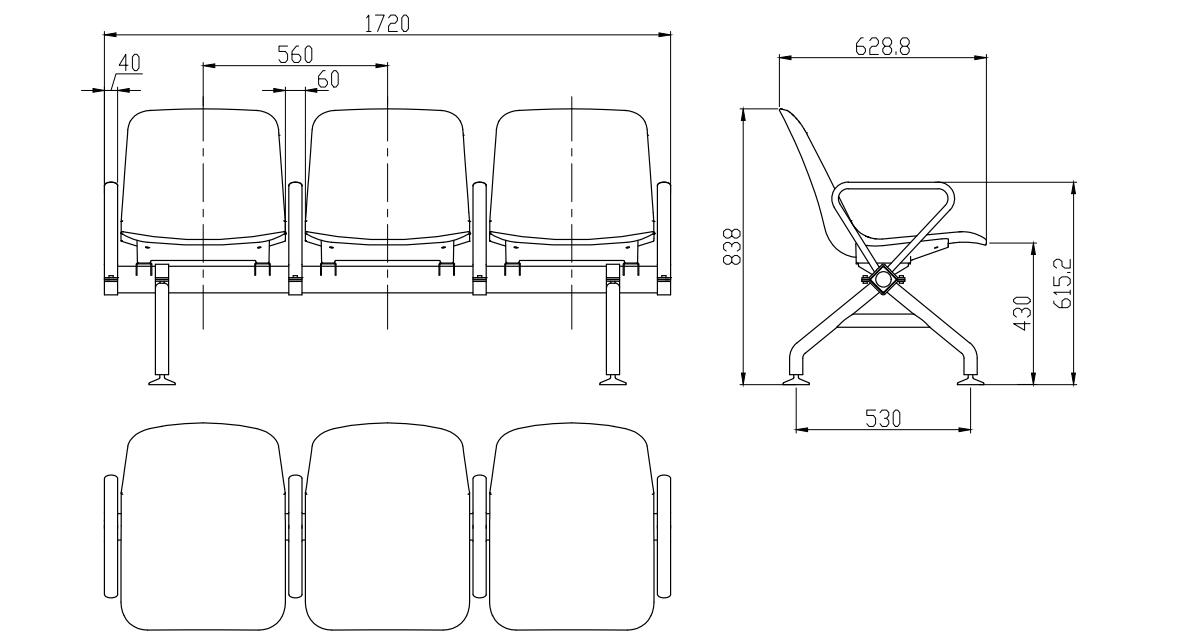

| Name: | Waiting chairs LS-501 |

|---|---|

Product Description

1) . Chair legs: Made by bending a circular tube with a wall thickness of 1.5mm and a diameter of 40mm, with a surface spray treatment.

2) . Armrest: It is formed by bending an elliptical tube with a wall thickness of 1.5mm and a shape of 20 * 40mm, and the surface is sprayed.

3) . Cross beam: Made of high-quality cold-rolled steel pipes with a thickness of 1.5mm and a diamond shaped quadrilateral shape of 60 * 60mm, stretched and formed. The surface is sprayed, and the installation is simple, sturdy, and stable, not easy to break.

4) . Seat back: It adopts super large mold (weighing 11 tons), 1300 tons high-speed injection molding machine, aviation grade impact resistant polypropylene material, combined with reinforced glass fiber modification, integrated injection molding, 3D curved surface modeling, and CFC cold curing foam free.

5) . The support frame is connected to the load-bearing crossbeam in a snap fit, using high-quality steel plates for bending and forming, with a surface spray coating treatment.

6) . Foot mat: Made of high-quality PP material in one piece.